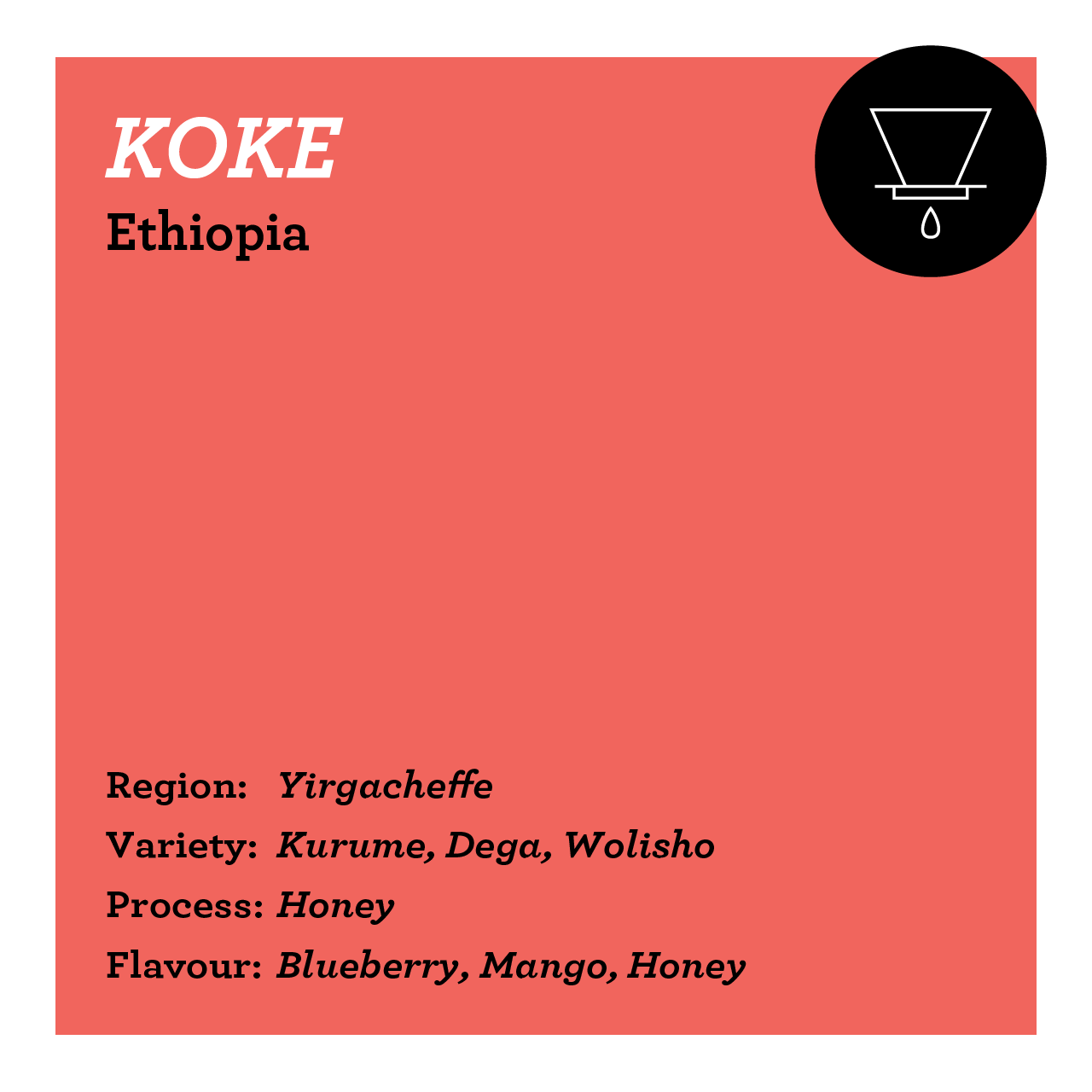

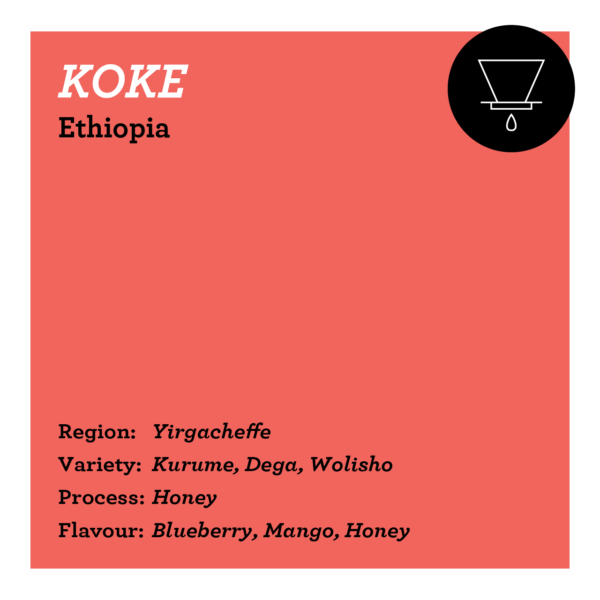

Coffee Production in Yirgacheffe

Coffee grown in the many districts and kebeles of the Gedeo Zone is often referred to as Heirloom varieties, many of which were propagated and distributed to farmers in the last 40 years.Trees grow in red brown fertile soil under the shade of many tree species including Bibira, Cordia Africana, and the subsistence crop Ensete ventricosum.

In the southern region of Ethiopia, farmers pick coffee selectively, harvesting only ripe cherries individually by hand. Pickers rotate among the trees every eight to ten days, choosing only the cherries which are at peak ripeness.

Many pickers average approximately 100 to 200 pounds of coffee cherries a day, which will produce 20 to 40 pounds of coffee beans. Each worker’s daily haul is carefully weighed, and each picker is paid on the merit of his or her work. The day’s harvest is then transported to the processing plant.

Washing Station

In 2022, due to the high demand of the cup profile Koke Honey offers, we were able to expand our procurement to an additional washing station near the Koke kebele. We are proud to introduce the addition of the Birbes Kela washing station that delivers the same high quality and tasting notes as the Koke washing station. Both are located in the Yirgacheffe district of the Gedeo Zone.

This lot of Koke Honey was sourced from a total of around 1200 smallholder farmers from Birbes Kela, Koke, Konga, Wedessa, and Tisho kebeles bring their harvested cherries for processing at the Koke and Birbes Kele washing stations.

The Birbes Kela washing station, located in the Birbes Kela kebele, is owned and operated by Semira Negash. Shortly after opening her washing station, Semira quickly established herself as a producer of high-quality coffees with a strong placement in Ethiopia’s 2021 Cup of Excellence.

Honey Processing

Harvested cherries are fermented in-cherry for two days prior to being pulped. The pulped coffee is then dried on raised beds to its optimal humidity.

Dry Milling

Coffee is prepared for export at Tracon Trading’s coffee cleaning and storage plant on 30,000 sq meters of land in Addis Ababa. The plant is equipped with modern Pinhalense coffee processing machines and a Buhler Z+ color sorter. The machine has the capacity of processing six tons per hour. Beans pass through a final hand sort on conveyor belts. The plant’s six storage silos have a capacity of roughly 15,000 metric tons. The warehouses are clean, with ample lighting and ventilation, which are ideal for maintaining the quality of the coffee.